Dozing Optimization – Get Immediate Cost and Emission Reductions

Bulldozers are often the most utilised machines in bulk earthworks.

Our proprietary simulation software:

Improves dozer productivity and reduces costs by 10–37%.

Reduces total earthworks costs and required dozing hours.

Cuts fuel use and carbon emissions.

Provides accurate budgets and schedules before work begins.

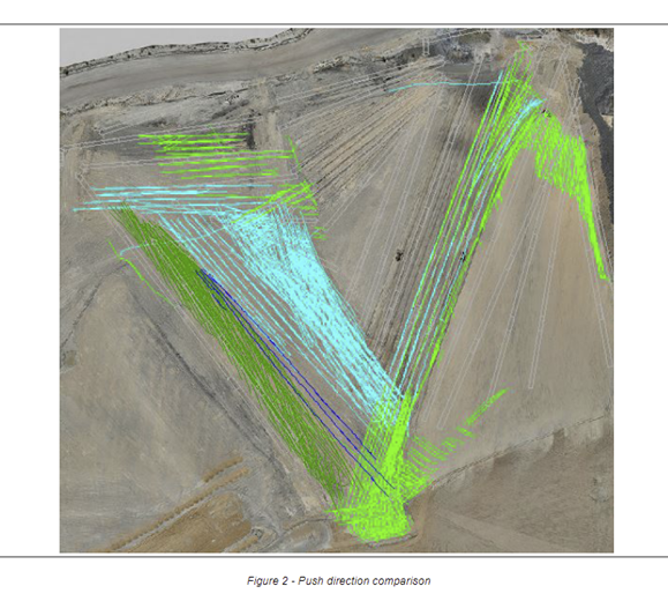

Compares different Pit and Dumping design Parameters in the Office, before Trialing in the Field

Create Mass Material Movement Tables for Volumes and Distances moved, Estimated Hours and estimated Production Rates

Create Final Landform designs and Pit Dozing Designs that are designed for Bulldozers.

The Know How to execute the Design Plan

-

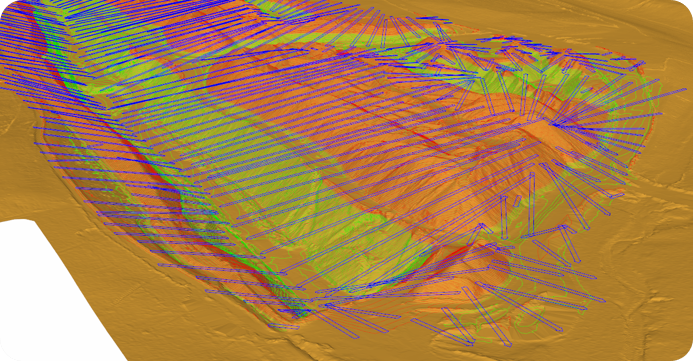

Cut and Fill Plans with Material Movement Locations

Taking the “Guess work” out of Reshaping operations with Desktop simulated Materiel Movement Analysis

-

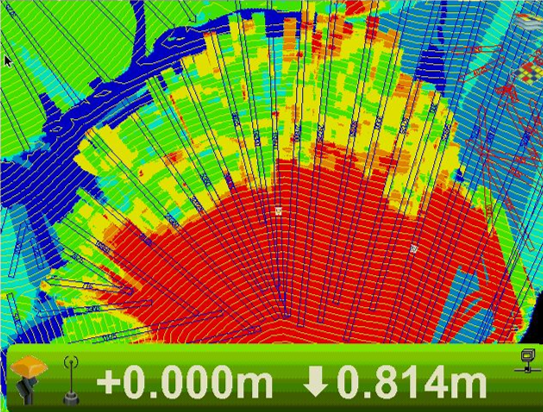

Material Mass Haul Tables

Calculate the estimated production and Schedules for Reshaping and Pit Dozing projects

-

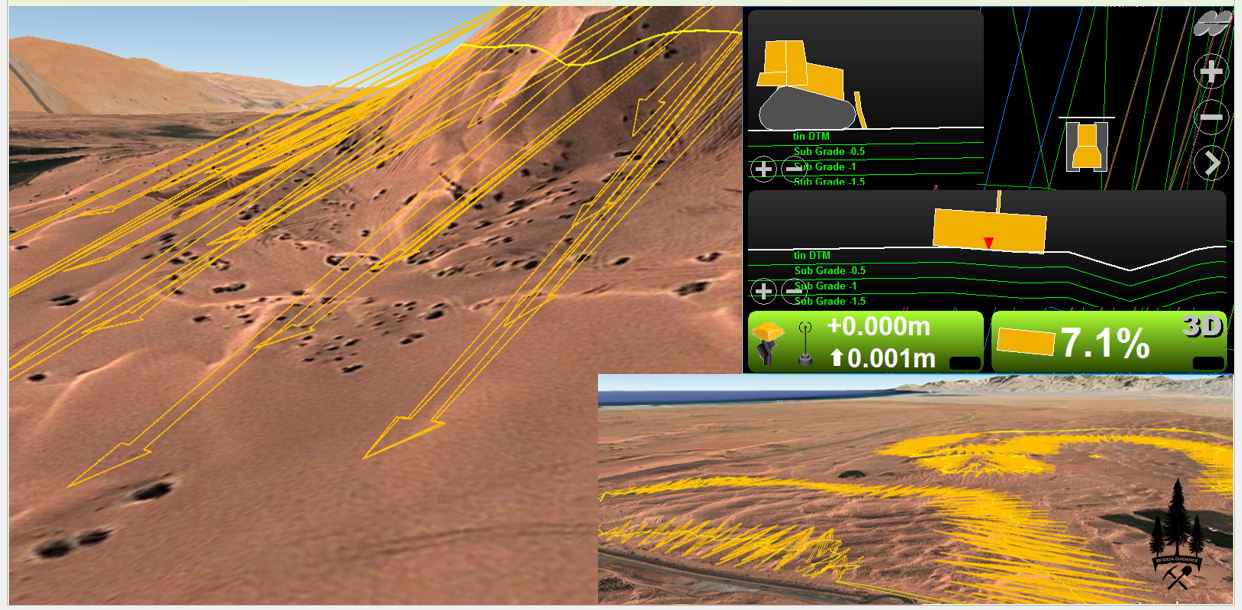

Overlay of Guidance Arrows to HP GPS dozers

Guidance to assist the Field Operations Team to deliver efficient Dozing Results.

-

Continuos Progress Monitoring

By Real-time data collection from the Bulldozers the Push Planning can be tracked to ensure the Field operation is performing their Tasks as efficiently as possible